Optimized Quadcopter Propeller Design for Urban Compliance

Client: Private Quadcopter Manufacturer

Objective:

To design a cost-effective, low-noise propeller for quadcopter that also generates the required thrust and efficiency while complying with urban noise regulations—without relying on extensive physical testing.

Challenges:

The main challenge in this project was the balance between competing criteria.

- Balancing thrust performance, noise reduction, and manufacturing cost.

- Ensuring compliance with local and national noise standards for urban environments.

- Minimizing reliance on costly and time-consuming laboratory tests.

Solution:

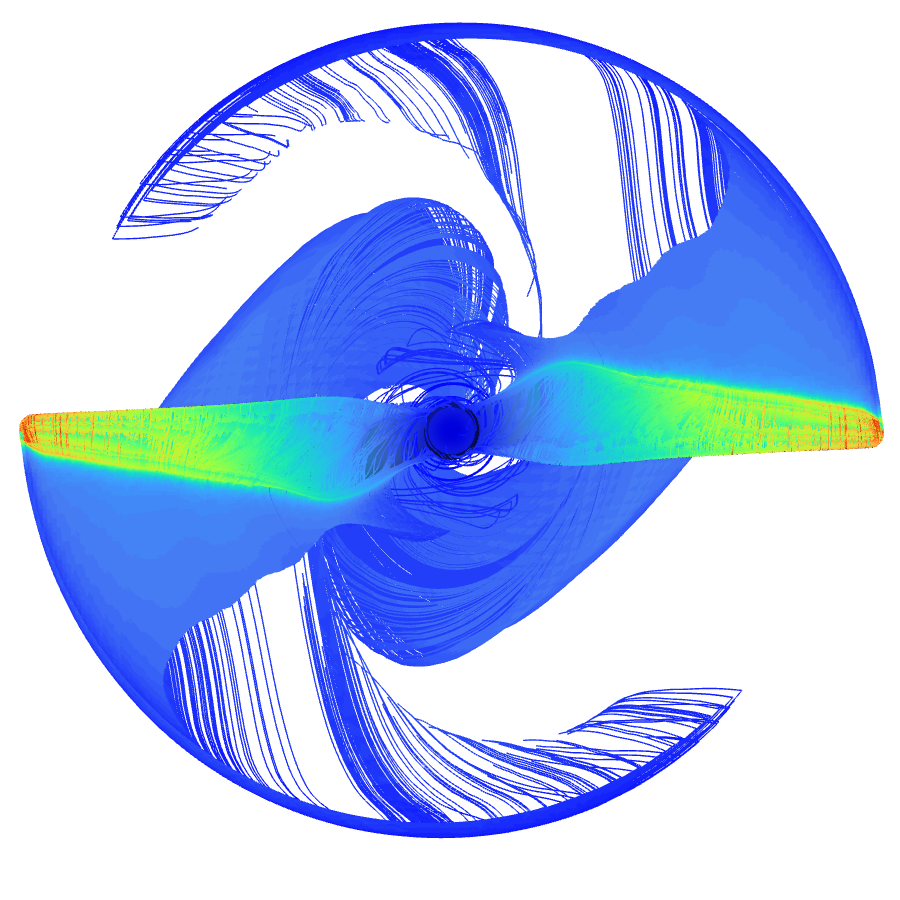

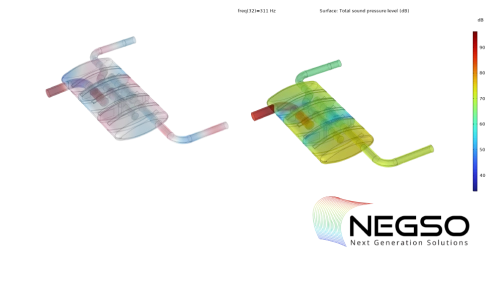

Using CFD (Computational Fluid Dynamics) and Aeroacoustic Simulations, we evaluated multiple propeller geometries to optimize the followings:

- ✔ Blade shape for improved aerodynamic efficiency.

- ✔ Material selection for cost-effective manufacturing.

- ✔ Acoustic performance to ensure compliance with noise standards.

Results:

- ✅ Enhanced thrust in both static and dynamic conditions.

- ✅ Reduced noise emissions, meeting urban regulatory limits.

- ✅ Cost-efficient design, eliminating unnecessary physical prototyping.

Conclusion:

Through advanced simulation-driven design, we delivered an optimized propeller that meets performance, noise, and cost requirements—ideal for urban UAV applications.

📩 Need a custom propeller design? Contact us today!

Quadcopter Propeller CFD Analysis