Optimized Muffler Design for Noise Reduction and Performance Maintenance

The client is a car part manufacturing company. They requested that redesign their muffler to reduce the noise by 20db and stay in compliance with the new EU and national regulations.

The muffler chamber in a car is part of the exhaust system and is designed to reduce noise produced by the engine.

Client: Automotive Parts Manufacturer

Challenges:

- Balancing noise reduction with engine efficiency.

- Preventing excessive backpressure, which can reduce engine power.

Solution:

To minimize manufacturing costs and reduce trial and error, CFD and finite element simulations are essential for calculating and optimizing the pressure drop and efficiency of the muffler.

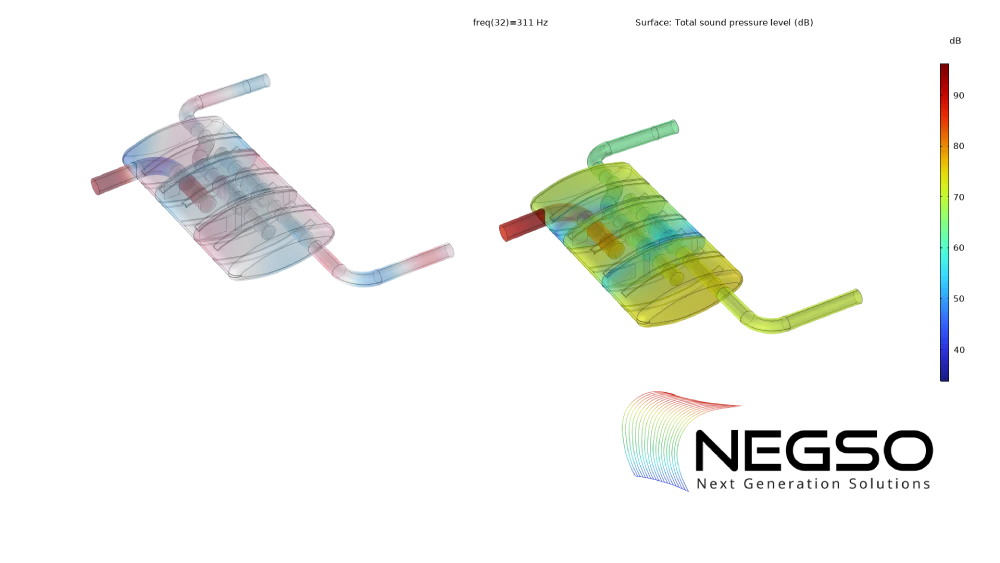

Using CFD (Computational Fluid Dynamics) and Computer Aided Engineering (CAE), we developed an advanced computational model to:

- ✔ Analyze the existing muffler’s efficiency and backpressure.

- ✔ Conduct full aeroacoustic simulations to assess noise levels at the exhaust outlet.

- ✔ Optimize the muffler’s internal geometry to enhance sound transmission loss while controlling pressure drop.

- ✔ Fine-tune the design to achieve the best trade-off between noise reduction and performance retention.

Results:

- ✅ Noise level reduced below 75 dB, meeting and exceeding regulatory requirements.

- ✅ Optimized backpressure, ensuring minimal impact on engine performance.

- ✅ Cost-effective redesign, eliminating excessive trial-and-error prototyping.

Conclusion:

Through high-fidelity simulations and optimization, we delivered a compliant, high-performance muffler that meets noise and efficiency targets, ready for next-generation automotive applications.

📩 Need an optimized exhaust system? Contact us today!

We Optimize your muffler design for reducing noise using Computational Fluid Dynamics (CFD).