Negso CFD Services

Fluid Dynamics Services

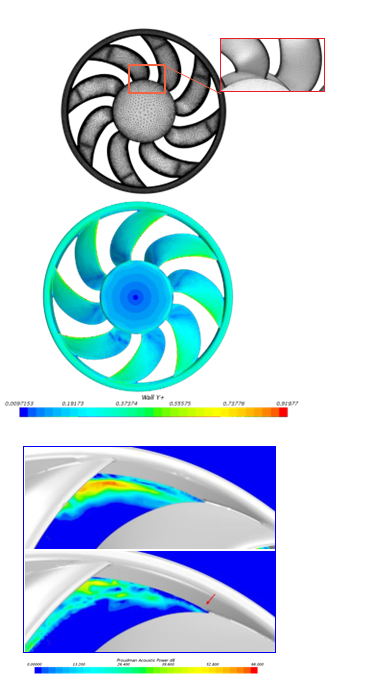

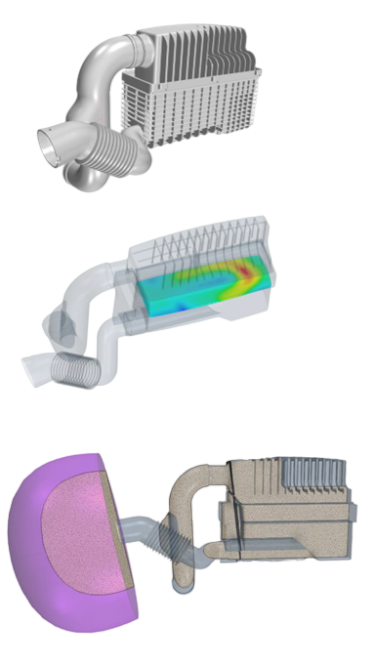

Our Fluid Dynamics services leverage Computational Fluid Dynamics (CFD) to analyse and optimise fluid flow, heat transfer, and related phenomena. From aerodynamics to acoustics, we help you understand and improve the performance of systems involving fluids.

Key Services:

- Aerodynamics: Optimize the aerodynamic performance of vehicles, aircraft, and other structures to reduce drag and improve efficiency.

- Thermal Management: Analyse heat transfer in systems to ensure proper cooling and thermal performance.

- Acoustics and Noise Analysis: Study sound propagation and noise generation to design quieter products and environments.

- Multiphase Flow: Simulate interactions between different phases (e.g., gas-liquid) for applications like mixing, separation, and combustion.

- Turbulence Modeling: Accurately predict turbulent flows to optimize designs in industries like automotive, aerospace, and energy.

Our Fluid Dynamics services are ideal for industries such as automotive, aerospace, energy, and HVAC, where understanding fluid behavior is critical to performance and efficiency.

Explore Our Services in Detail

Each of our services is backed by in-depth expertise and advanced tools. Visit our dedicated pages to learn more about:

What is CFD?

What is Computational Fluid Dynamics (CFD)?

CFD (Computational Fluid Dynamics) is a broad field that involves solving fluid flow and heat transfer problems using numerical methods.

Computational Fluid Dynamics (CFD) is a field within fluid mechanics that uses numerical methods and algorithms to simulate and analyze fluid flow behavior.

It is a powerful method for predicting the complex interactions of fluids (liquids and gases) with structures, surfaces, and each other in various engineering applications.

How CFD Helps Your Projects

- Optimized Product Design

CFD analysis allows teams to virtually test and refine designs by visualizing airflow, water flow, or chemical mixing. This leads to improved efficiency, reduced drag, and optimized performance. - Reduced Costs and Development Time

Identifying potential issues through simulation lowers the need for multiple prototypes or extensive physical testing. As a result, product development cycles become faster and more cost-effective. - Enhanced Reliability

By accurately predicting fluid behavior under a wide range of operating conditions, CFD helps engineers develop robust, failure-resistant systems, minimizing downtime and warranty claims. - Cross-Industry Versatility

From aerospace and automotive to consumer products and environmental engineering, CFD offers flexible applications. Whether you’re a project manager seeking to streamline a process or a research student exploring advanced fluid behaviors, CFD provides valuable insights. - Data-Driven Decisions

With simulation results in hand, teams can make informed design choices, ensuring that products not only meet but exceed performance expectations.

Interested in leveraging CFD to advance your engineering projects?

Contact us today for a free consultation session and discover how our expertise can take your designs to new heights.