Negso FEA Services

FEA Consultancy Service

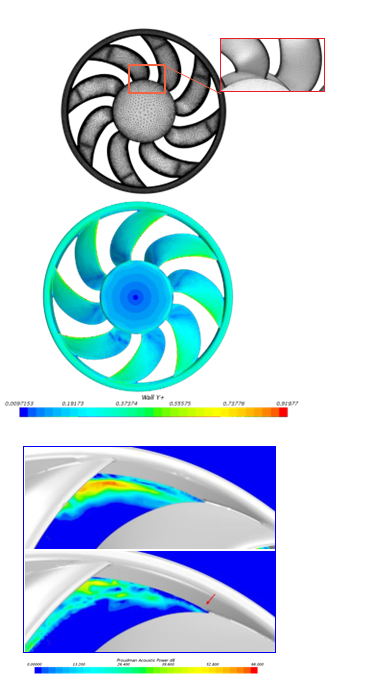

Using advanced Finite Element Analysis (FEA), we help you predict how your design or product will function in real-world scenarios.

Key FEA Services:

- Structural Analysis: Evaluate stresses, strains, and deformations in your designs under static, dynamic, and thermal loads.

- Fatigue and Durability: Predict the lifespan of components under cyclic loading to prevent failure.

- Impact and Crash Simulations: Analyse the effects of impact and crash scenarios on structures, ensuring safety and compliance.

- Vibration Analysis: Study the dynamic response of structures to vibrations, reducing the risk of resonance and failure.

- Thermal-Structural Coupling: Investigate the effects of thermal expansion and contraction on structural integrity.

Whether you're designing automotive components, aerospace structures, or industrial machinery, our Solid Mechanics services provide the insights you need to make informed decisions and optimise your designs.

Explore Our Services in Detail

Each of our services is backed by in-depth expertise and advanced tools. Visit our dedicated pages to learn more about:

What is FEA?

What is Finite Element Analysis (FEA)?

Finite Element Analysis (FEA) is a computational method used to predict how structures respond to environmental factors such as force, heat, and vibration, by dividing the subject into smaller, simpler parts called finite elements.

Key Benefits of FEA

- Early Risk Detection

FEA helps identify potential weak points or failure locations in your design before any physical prototypes are built. This enables you to address critical issues upfront, minimizing costly design changes later. - Reduced Development Costs

By predicting real-world performance through simulations, you can significantly cut down on physical testing and multiple prototype iterations. This not only saves time but also lowers overall project expenses. - Optimized Performance

Through iterative simulation, FEA provides deep insights into how material selection, geometry, and load conditions affect performance. Such data-driven optimizations boost product efficiency, durability, and safety. - Accelerated Time-to-Market

Streamlining the design process with digital simulations allows your team to focus on product improvements instead of repetitive testing. The result is a faster launch cycle and a competitive edge in the market. - Versatile Applications

FEA is applicable across industries—from aerospace and automotive to consumer products and medical devices. Whether you’re a project manager refining an existing design or a research student exploring new concepts, FEA offers unparalleled flexibility.

Why FEA Matters

By incorporating Finite Element Analysis into your engineering process, you gain a proactive tool for risk management, cost reduction, and performance enhancement. Whether you’re looking to validate a new concept or optimize an existing product, FEA empowers you to make informed decisions backed by real-time simulation data. This translates to superior outcomes, higher-quality products, and greater confidence in every phase of your project’s development cycle.

Ready to explore how FEA can elevate your engineering process? Contact us today for a free consultation session and discover the difference Finite Element Analysis can make in your next project.